Project Description

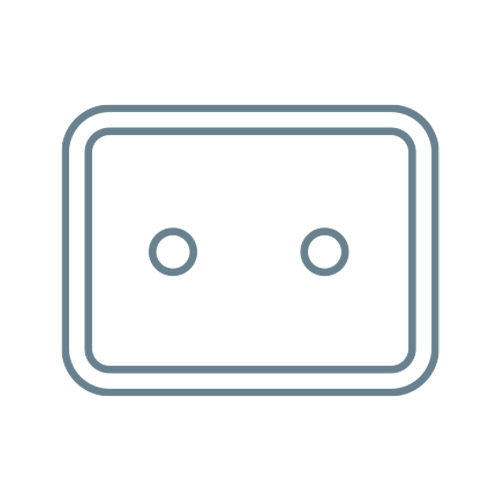

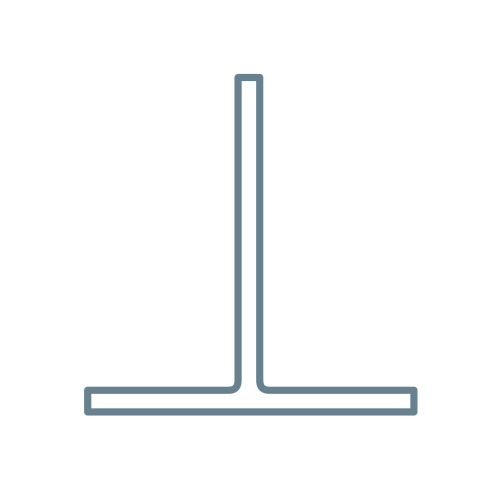

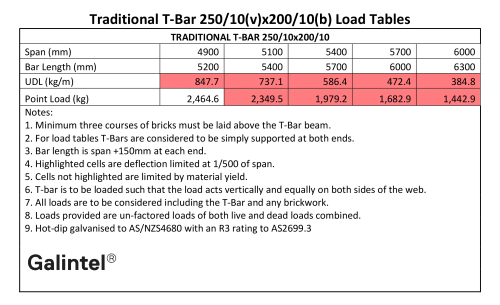

Traditional T-Bar

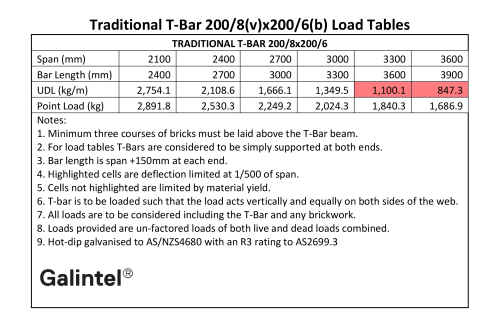

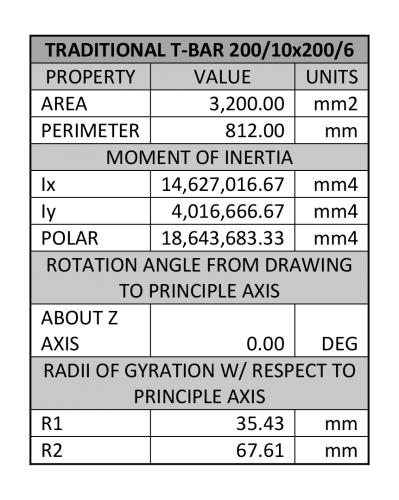

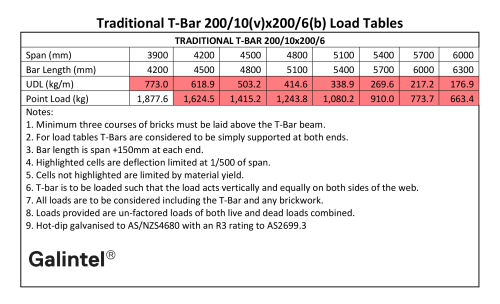

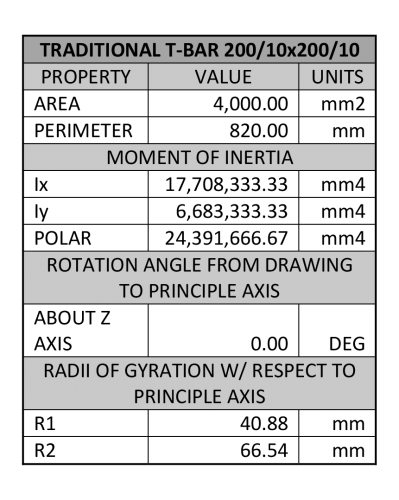

BSD Traditional T-Bar is a fully machine welded structural lintel manufactured in Australia using 300MPa steel. Traditional steel sections are used in the support of brickwork over large clear openings and are not reliant on composite action.

Size & Stock Length Guide:

| 200/6 MM (V) 200/6 MM (B) | 200/8 MM (V) X 200/6 MM (B) | 200/10 MM (V) X 200/6 MM (B) |

|---|---|---|

| 900 | 2400 | 4200 |

| 1200 | 2700 | 4500 |

| 1500 | 3000 | 4800 |

| 1800 | 3300 | 5100 |

| 2100 | 3600 | 5400 |

| 2400 | 3900 | 5700 |

| 6000 | ||

| 6300 |

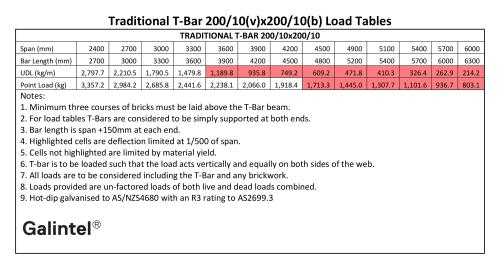

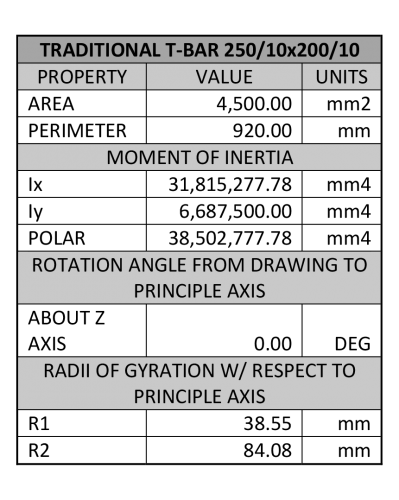

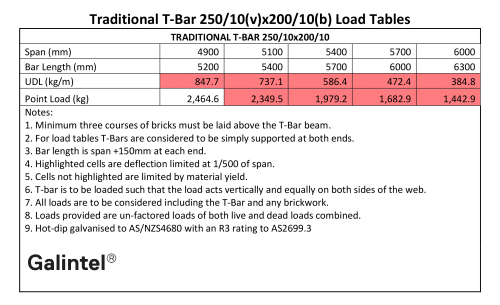

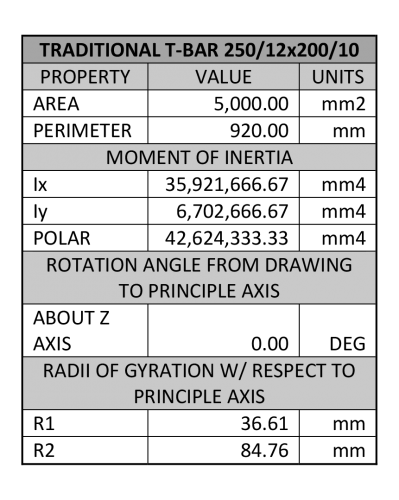

| 200/10MM (V) X 200/10MM (B) | 250/10MM (V) X 200/10MM (B) | 250/12MM (V) X 200/10MM (B) |

|---|---|---|

| 2700 | 5200 | 5200 |

| 3000 | 5400 | 5400 |

| 3300 | 5700 | 5700 |

| 1800 | 3300 | 5100 |

| 3600 | 6000 | 6000 |

| 3900 | 6300 | 6300 |

| 4200 | ||

| 4500 | ||

| 4800 | ||

| 5200 | ||

| 5400 | ||

| 5700 | ||

| 6000 | ||

| 6300 |

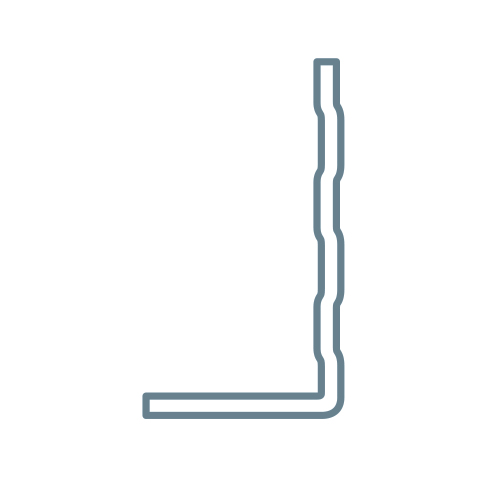

* (V) is the vertical section dimension, (B) is the base section dimension.

Features

- Hot-dip galvanised to AS/NZS4680

- Comply with Australian Standards and Building Code requirements

- Product certified by Unisearch Limited

- Fully machine welded

- 300 MPa grade steel

- Not reliant upon composite action

- R3 Durability Rating in accordance with AS/NZS2699.3

- Fully engineered and university tested

- Compliant with relevant Australian Building Codes and Australian Standards

- 25 year performance warranty

- Labelled and barcoded

Benefits

- Superior performance

- Easy transportation, storage and handling

- Long life and durability

- Cost effective

- Easy identification

- Control Joints

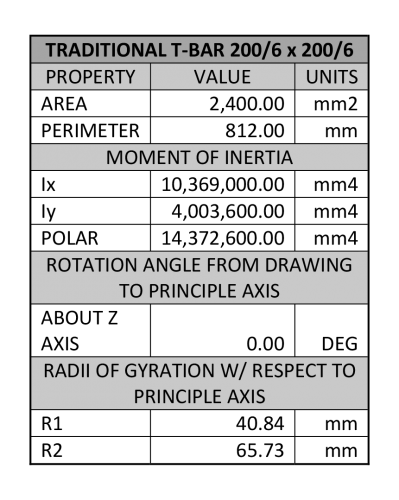

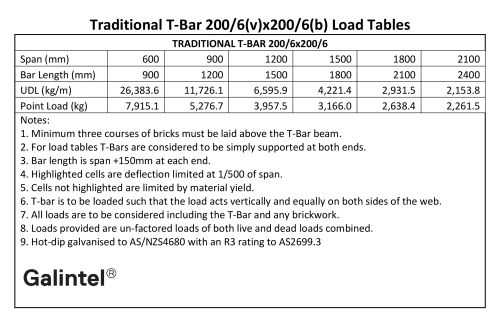

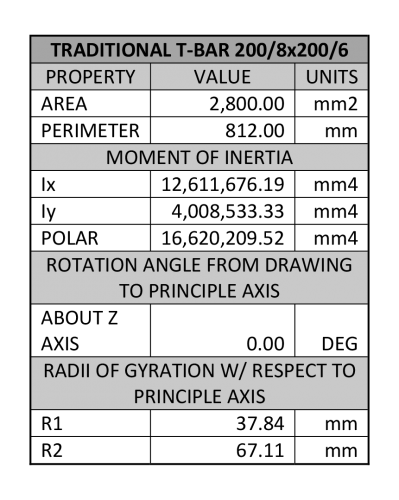

Technical information

Control Joints

Where control joints are used as a required structural element, loading of the lintel should be reduced by one third.

Installation

Place Traditional T-Bar in position on brick piers, with minimum end bearing of 150mm. Prop before bricklaying. Props must be no further than 1.2 metres apart and must remain in place until mortar has fully cured. The same number of courses must be laid internally and externally to prevent twisting of the T-Bar.